An interesting and common application of our machines is laser processing of glass. Glass is a brittle material, that tends to form micro-cracks on its surface and edges. When exposed to mechanical or thermal stress, these cracks can advance into the glass and result in the sudden fracture of the item. Thus the challenge for the laser engraving process is to avoid creating micro-cracks.

With our picosecond laser CEPHEUS, because of its short pulses, only little heat induction occurs into the glas while maintaining high precision and sharpness of the marking. Consequently, the workpiece is not exposed to significant stress, which results in a high quality marking without creating any micro-cracks during the process.

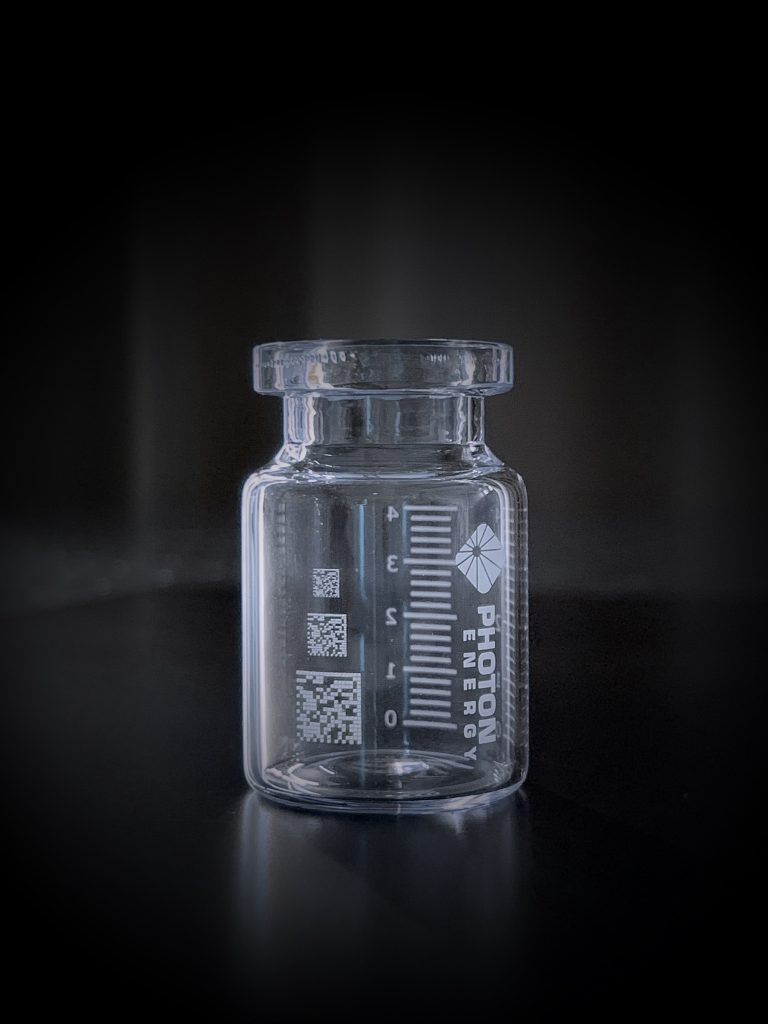

The picture depicts a vaccine vial which was marked with our leading ultrashort pulse technology and whose mechanical stability is thus not compromised.