Laser processing of glass

Applications for glass laser processing on the surface as well as in the material

Glass proves to be a versatile material and unfolds its potential applications in a wide range of industries. This is due to a wide range of glass types, which differ in their production, chemical composition and behavior during processing. The selection of the appropriate glass type depends heavily on the specific application and the associated requirements. Using a laser, various processes can be implemented on glass. The decision for a laser system and process is made according to the required quality and performance profile of the respective application.

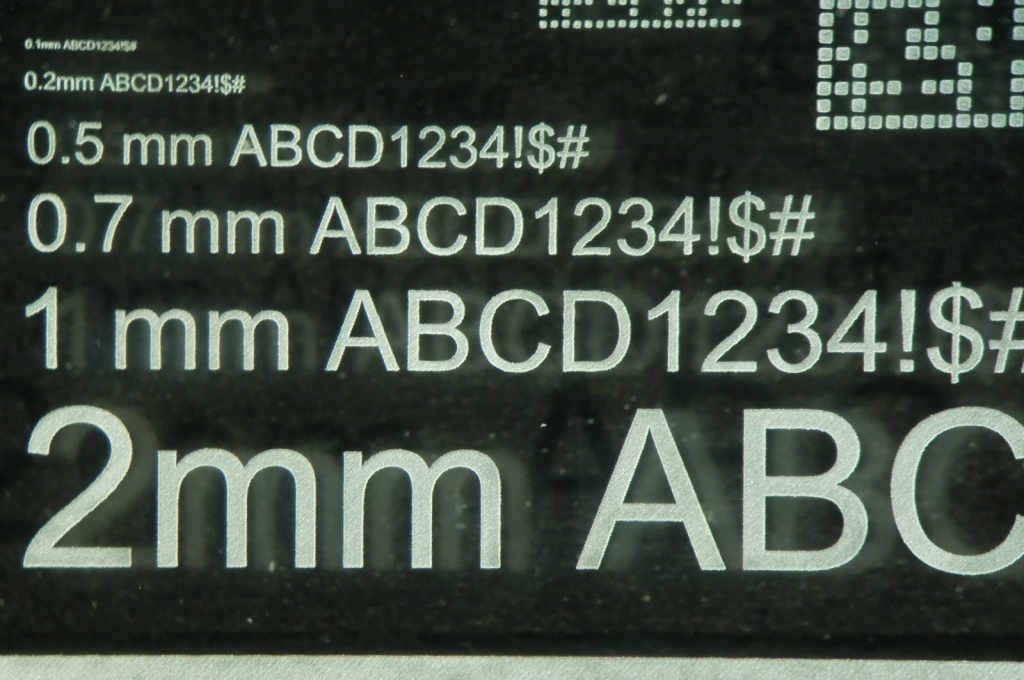

Surface Marking

Appropriate laser parameters for marking of glass depend strongly on the particular glass type used. Standard sheet glass or lead glass and many types of optical glasses are well processed using LEO – or for more specialized cases – our CEPHEUS laser.

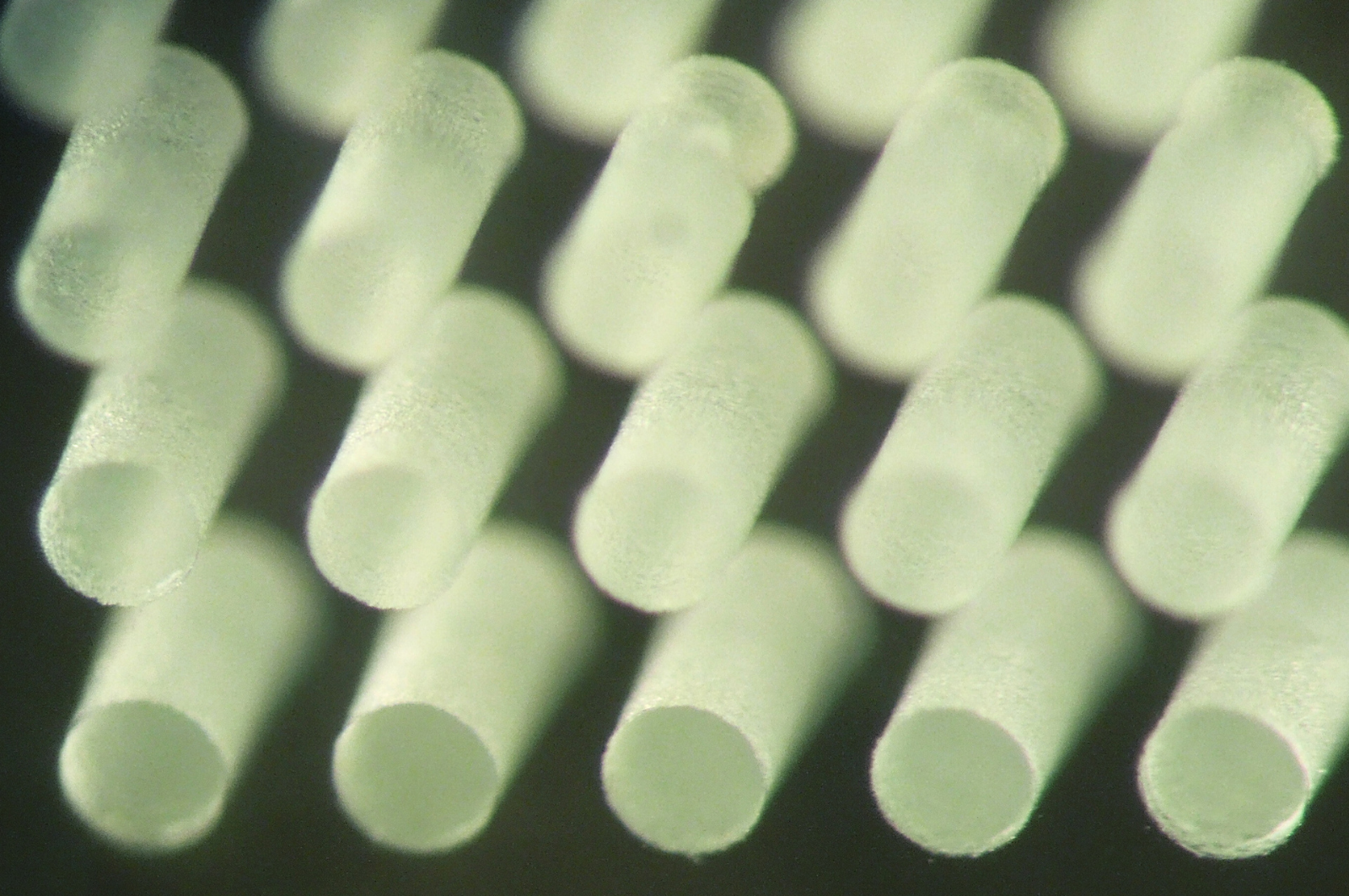

Cutting

Laser cutting of glass has many advantages compared with conventional cutting methods. Laser glass cutting is contactless, almost debris-free, zero-gap processing. In many cases glass parts cut with lasers don’t require post-processing.

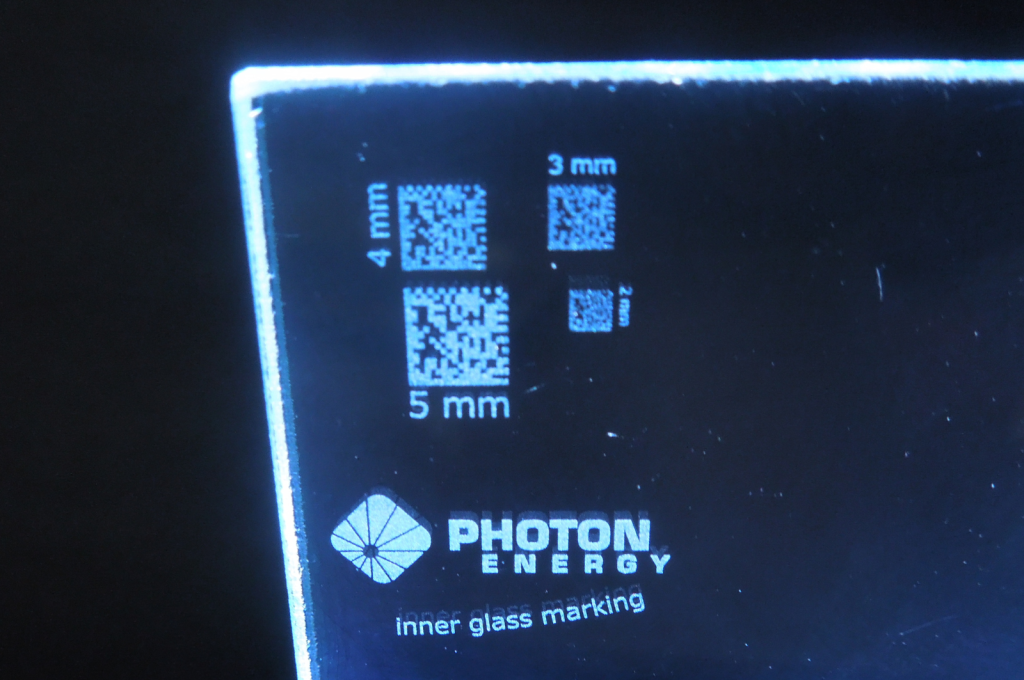

Inner Glass Marking

With our lasers, marking very close to the surface is possible without damaging the surface. This can be realized at high process speeds, which makes our product highly competitive.