Vision Systems

Cameras that make your work better

The classical way of positioning the marking on a workpiece is a redlight frame or a marking simulated by a laser pointer. These techniques remain sufficient for many applications.

If the user wants to see the exact position of the marking on the workpiece, there’s no better solution than a camera system.

PHOTON ENERGY’s different camera solutions enable fast and exact markings. The range of possibilities reaches from simple positioning help (MAP) to fully automatic positioning on a μm-scale with our SMART option.

Functions

MAP Marking by augmented positioning

MAP generates pictures of the marking area by using different available camera systems (CamVision or CamVisionPro). Our image correction algorithm adjusts those pictures and displays them in our laser software PHOTONmark.

The marking can be placed on the picture which equals placing it directly on the workpiece. This ensures placing the marking exactly where you want it.

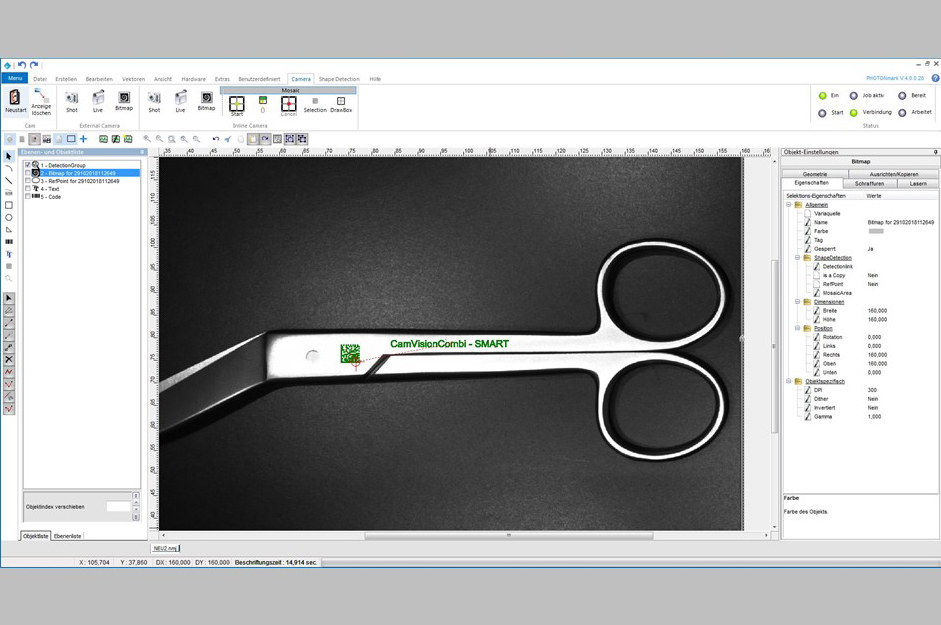

SMART Simple Marking by Augmented Reality Targeting

The function package SMART is available for the CamVisionPro and CamVisionCombi versions. With this solution it is possible to integrate Pre- and Post-processes into the procedure.

An assistant intuitively introduces the Shape-Detection capabilities of our system.

The camera systems

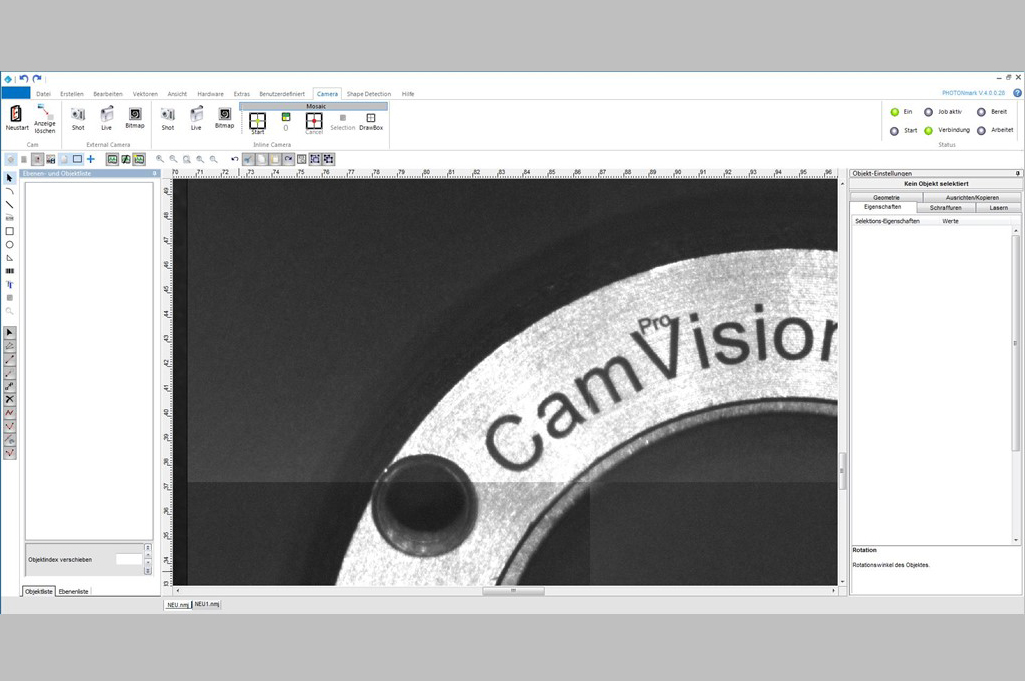

CamVision

The most simple method of depicting the marking field in the laser software is CamVision. The camera looks onto the marking field sideways at an angle. The picture is adjusted for the angle and then displayed to the user. With MAP and drag-and-drop all elements that you wish to mark can be placed on the picture. The marking result is visible before the marking process even started. This system makes it easier to set up the laser process and minimizes rejects.

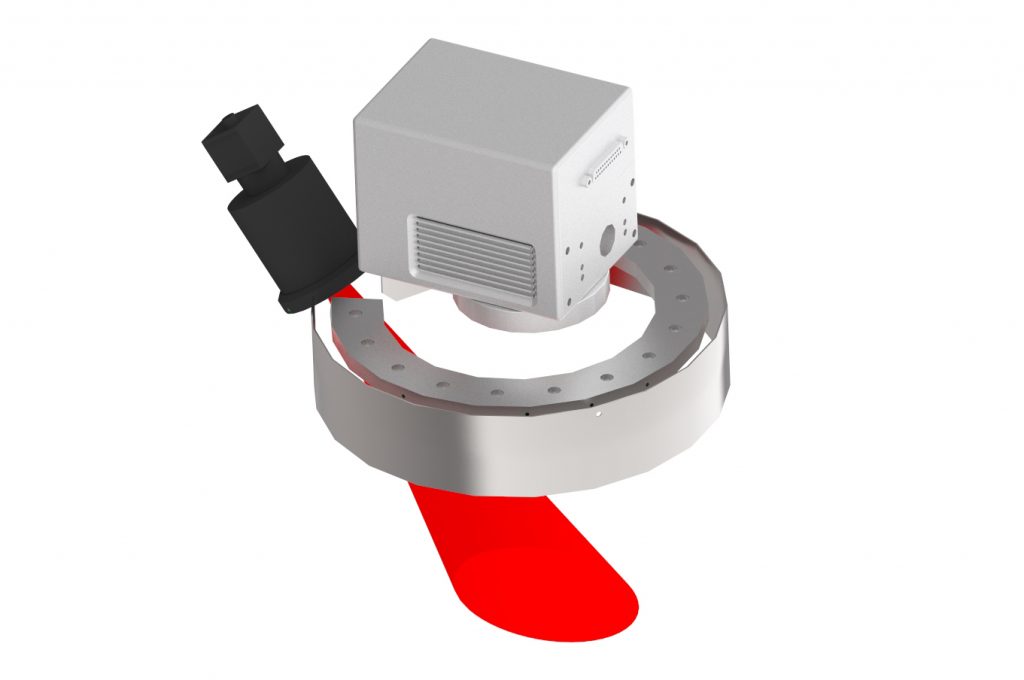

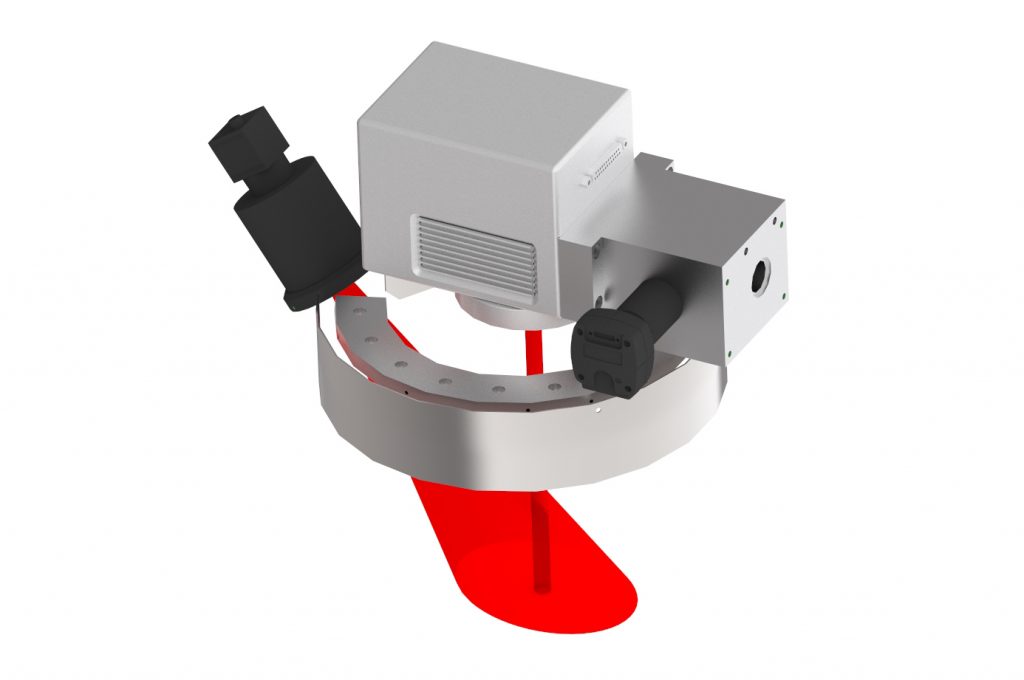

CamVision Pro

High-precision positioning is possible with CamVisionPro.

The camera looks onto the marking field through the scanner unit and focal lens. To achieve a maximum of precision the pictures are adjusted by the most advanced image correction algorithms.

The size of each individual picture is smaller with this method, but a larger image can be produced by merging those pictures to a larger grid.

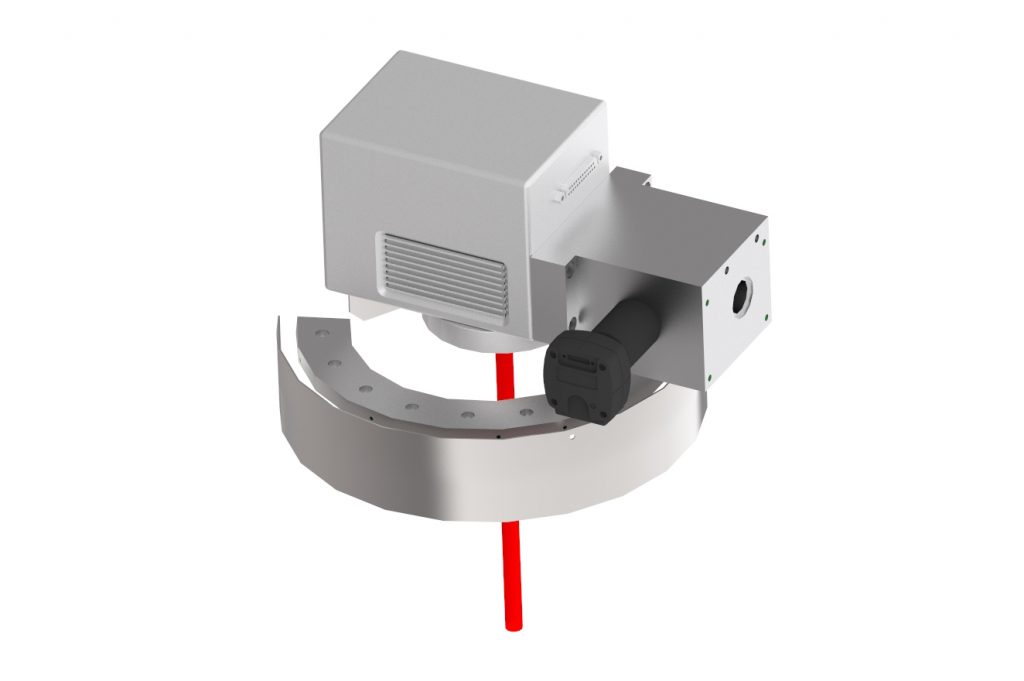

CamVision Combi

Combining CamVision and CamVisionPro delivers a maximum of flexibility and precision.

The lateral camera generates a complete picture of the marking area. Finding parts on the workpiece that are of interest for the marking process is easy that way. This region of interest (ROI) can then be looked at with CamVisionPro which delivers high-resolution pictures. This means that filigree areas can be examined without having to screen all of the marking field. This equals significant savings in process time.