Applications on Ceramics

Applications like engraving and color change

Ceramics are materials characterized by high abrasion resistance and hardness. Processing these components requires laser sources providing excellent beam quality. This also facilitates marking with character heights of less than 0.5 mm.

Common fields of application

Automotive

Medical

Sensors

Electronics

Engraving

Almost all ceramics can be engraved with our lasers. Both the good beam-quality as well as the ultrashort pulses of our lasers enable stress-free processing with no heat-induced effects.

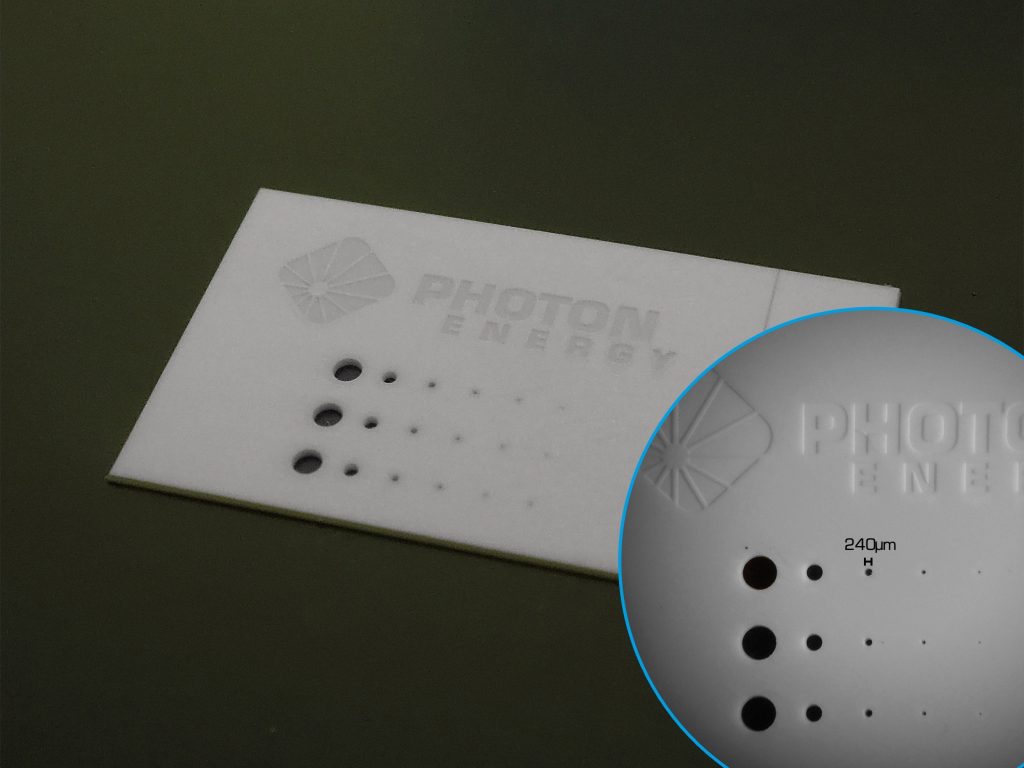

Drilling

Similarly, microscopic holes can be drilled in ceramics with our ultrashortpulse technology, as depicted here. The processing with our picosecond lasers results in clear cutting edges without inducing any micro cracks in the material.

Color change

Depending on the material composition, a color change can be realized on a variety of different ceramics.

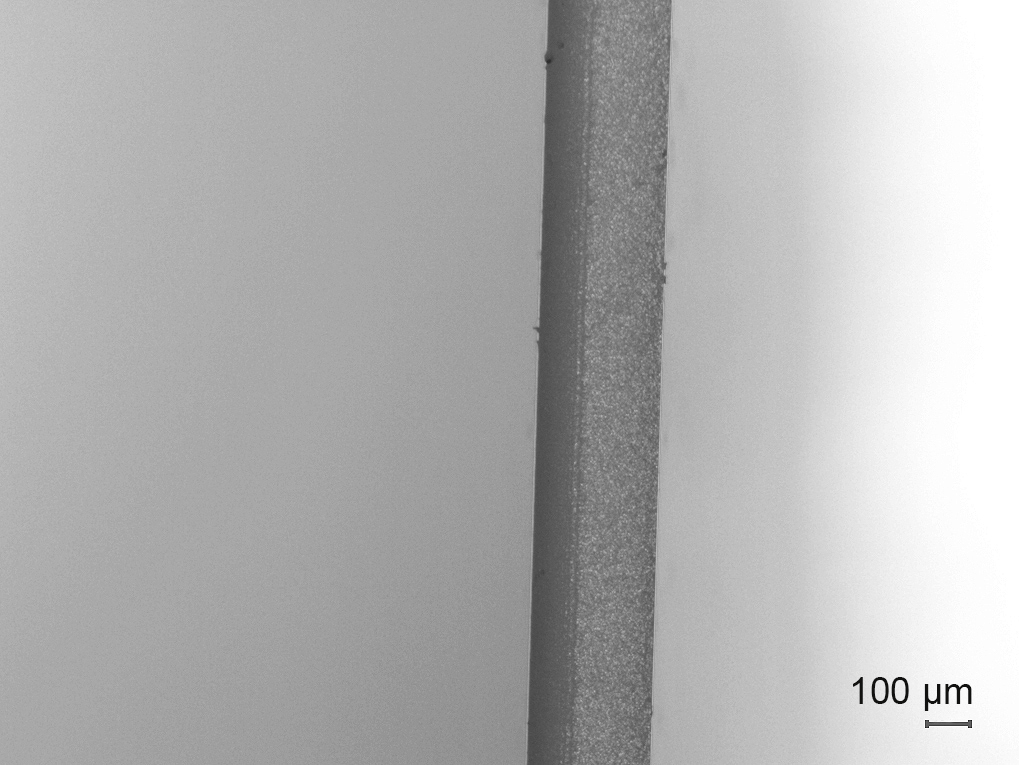

Scribing and separating

Scribing describes a process, which only scribes the material without cutting it altogether.The resulting rated breaking line allows for an easy separation of the sides of the workpiece along this edge. The picture shows the cross-section of a cermamics disk seperated using the described scribing technique. The darker area (left) is processed (scribed) by the laser, whereas the right part of the edge is the breaking point. The picture illustrates the homogeneity and thus high quality of the dividing line.