Applications on Plastics

A variety of applications like foaming, carbonization and cutting

While a significant portion of the laser beam is reflected during laser marking and processing on metals, the various methods for laser marking on plastics rely on the absorption of the beam into the material. Depending on the type of plastic and other factors, different laser sources and laser parameters are suitable for implementing the process. In general, plastics can be marked more quickly than metals, for example, due to their low thermal conductivity.

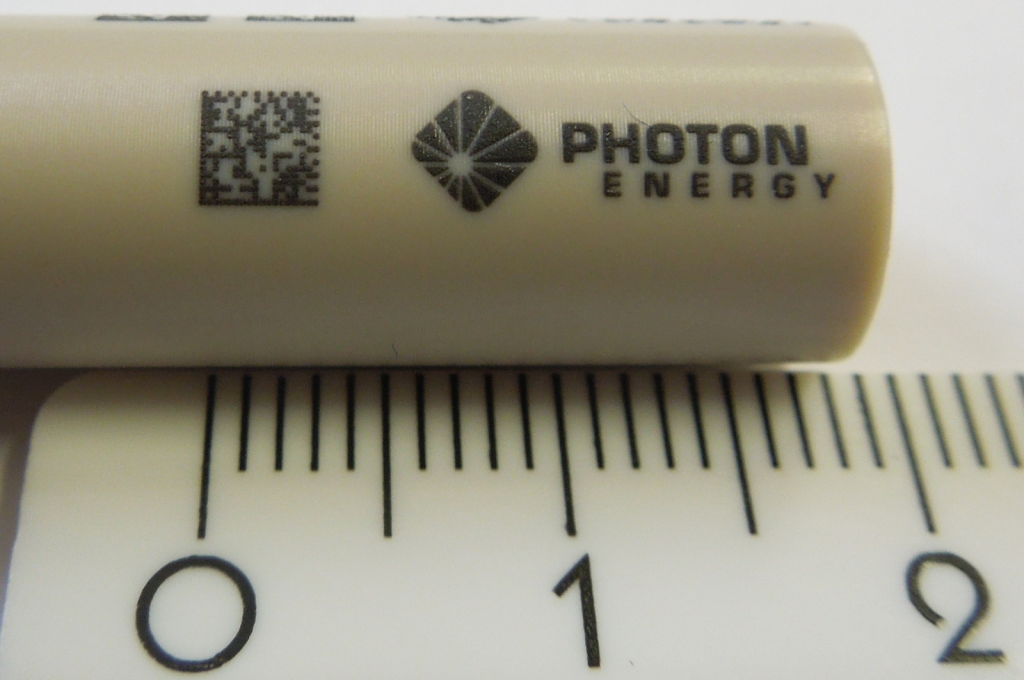

Carbonization

Many types of plastic react to the laser by producing carbonization effects, which can be used to achieve a dark coloration. This ensures a very good contrast in light-colored plastics. The important parameter for this effect is the absorption of laser light by the material. This is why it may be beneficial to use a green-light laser for some plastic types.

Engraving

Engravings with material removal are particularly suited for thermosetting plastics. A good legibility is achieved due to the reflection contrast of the engraving.

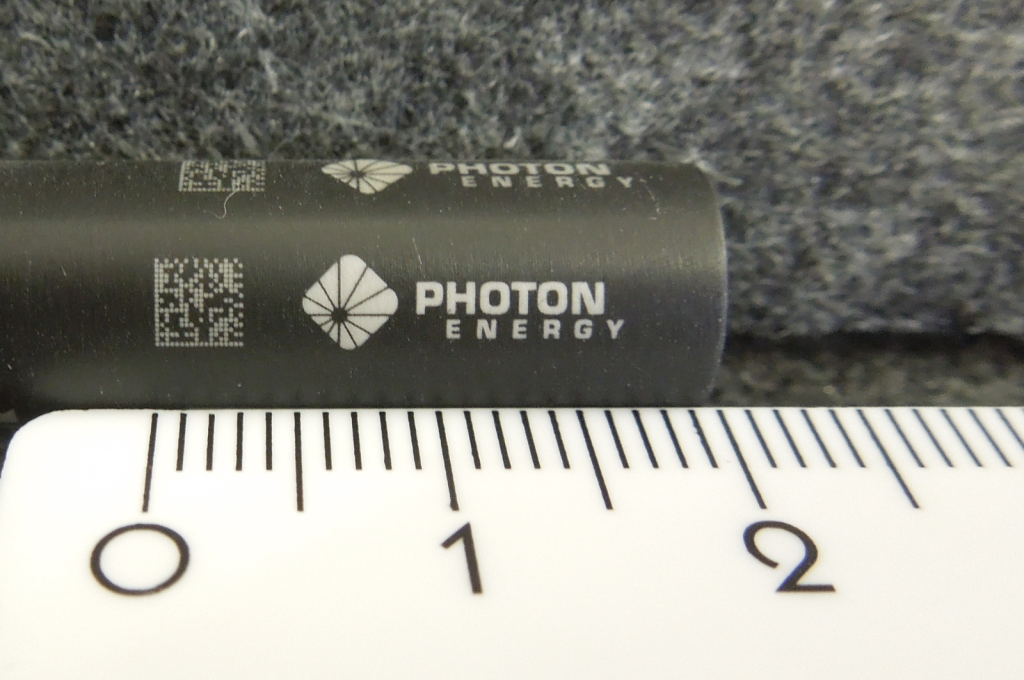

Foaming

In certain plastic compositions the plastic foams when exposed to laser light. This changes the color, for example from black all the way to white or a soft brownish color. This ensures an excellent color contrast. Since this type of labeling can be performed with very low power, the method can be used for high-velocity applications.

Material Removal

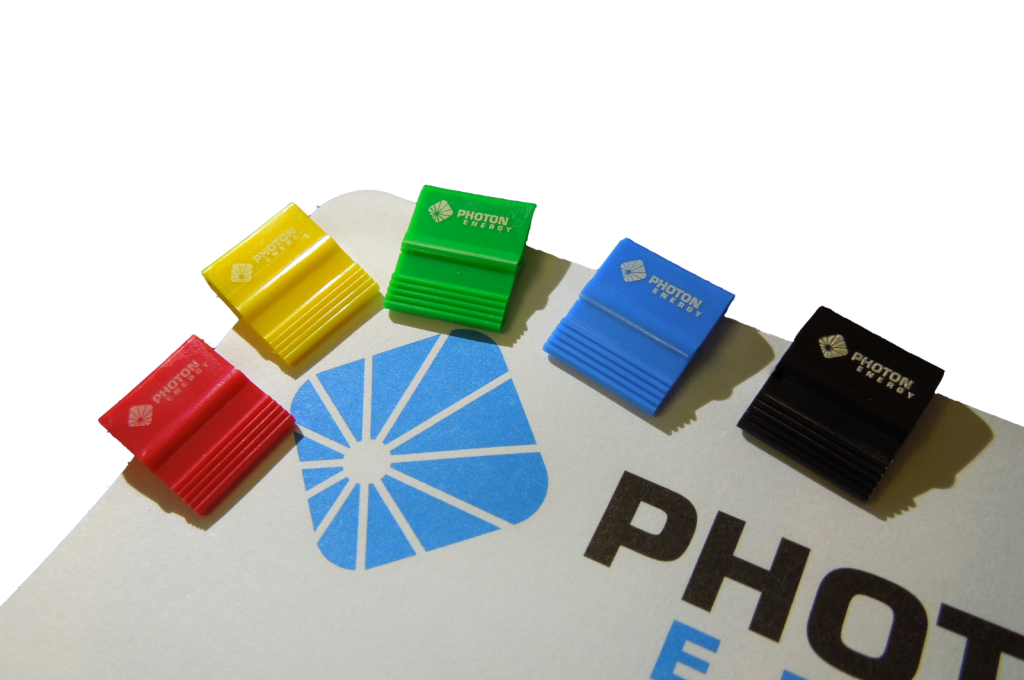

An outstanding contrast can be achieved by removing the upper layer in coated plastic parts. Material combinations whose top layer interacts more strongly with the laser light than the substrate material are particularly suited for this method.